Back

Your Leading Industrial Distributor

Back

Back

Back

Motors

Filter Products

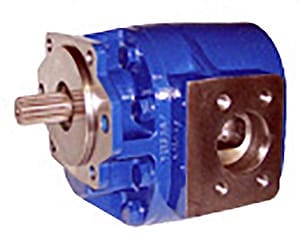

Bosch Rexroth-Industrial Hydraulics

Bosch Rexroth Swashplate Piston Motors

Contact Us For Pricing And Availability

If you’re interested in any of our products, or you have any questions about pricing and availability, let our team know today. We’re here to help!