Hydac

HYDAC Check & Load Control Valves

Womack Machine Supply Company proudly partners with Hydac to deliver the finest Load Holding Valves available. Our collaboration ensures that customers in multiple locations across the United States have access to these exceptional products, click here to see available locations. Our commitment to excellence, combined with the reliability and performance of Hydac, guarantees that you receive top-quality Load Holding Valves components for your specific needs.

The HYDAC range of direct and pilot operated check valves provide a broad selection of cartridge and inline products with operating pressure rating of up to 6000 psi (420 bar). All valves have a one piece body design and hardened balls or poppets. This provides an excellent product with reliable seating, 2 drops/minute maximum internal leakage, dirt-tolerance and long life.

Check Valves offer optional bias springs and flow capacity up to 44 gpm (165 l/min). Check valve cartridges fit into Industry standard cavities. A wide selection of cracking pressures are available from 5 to 70 psi (0.35 – 5 bar). Thus they could be used not only as a conventional check but also as a low pressure relief valves.

Pilot Operated Check Valves are available for flows up to 40 gpm (150 l/min) and pilot ratios 3:1 and 4:1. These valves positively lock a load from port 1 to port 2 until pilot pressure applied to port 3 is sufficient to unseat the valve. This flow path provides for higher flow rating in a given cavity, excellent stability and repeatability. They also fit into the same cavity as HYDAC counterbalance valves. These valves provide a low cost alternative to load control when the dynamics of neither overrunning loads nor load release speed are factors to be considered in the design of the hydraulic circuit. They are used for:

- Position load locking.

- As an alternative to counterbalance valves where neither the overrunning loads or release speed are factors in the application.

Single Pilot-to-Open Check Valves and Dual Pilot-to Open Check Valves are inline housed, pilot operated, hydraulic check valves for use as a blocking or load holding device for flow rates up to 20 gpm (80 l/min) and 6000 psi (420 bar). They feature:

- Hardened closing element in a check valve to ensure extended service life and 2 drops/min maximum internal leakage

- Multiple bias spring options for back pressure application flexibility

- Optional sealed pilot piston

- Check section serviceable as a cartridge

- All zinc-plated external cartridge surfaces

- Aluminum or steel inline housings

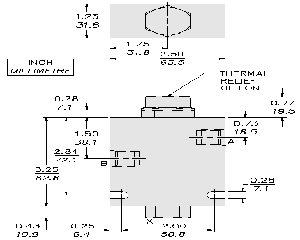

Counterbalance Valve RS08-01 is a compact cartridge design with operating pressure up to 5000 psi (350 bar) and flow rate up to 10 gpm (38 l/min). These valves are used for

- Precise control of overrunning loads

- Positive load holding in any position

- Protection from pump cavitation

- Thermal expansion relief protection

- Preventing actuators from running ahead of the pump supply

Counterbalance Valves have:

- A built in check valve feature allowing free flow in one direction

- A relief feature controlling flow in the other direction

- A pilot signal that overrides the relief setting providing the counterbalance function

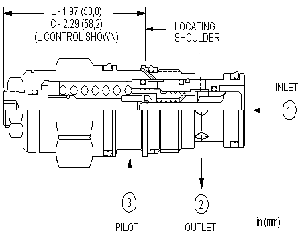

RP08A-01

Check Valve, Pilot-to-Open, Poppet Type

Up to 10 gpm (38 l/min) • 6000 psi (420 bar)

Description

A screw-in cartridge, poppet type pilot operated check valve for use as a blocking or load holding device.

Operation

The RP08A allows flow from port 2 to port 1, while normally blocking flow from port 1 to port 2. The valve remains closed by bias spring until sufficient pressure is applied at pilot port 3. The cartridge has 3:1 and 4:1 optional pilot ratios, meaning that at least one-third or one-fourth (respectively) of the load pressure held at port 1 is required at port 3 to open the valve. A sealed pilot piston option is available.

Features

- Hardened poppet to ensure extended service life and low leakage

- Additional reseating spring for fast and reliable closing

- Optional sealed pilot piston

- Higher flow rating and low pressure drop due to pilot port at 3.

- Same cavity as counterbalance valve RS08.

- All external surfaces zinc-plated or specifically treated

- Industry common cavity

HYDAC Cartridge Valves

HYDAC Cartridge Valves Overview

RP10A-01

Check Valve, Pilot-to-Open, Poppet Type

Up to 16 gpm (60 l/min) • 6000 psi (420 bar)

Description

A screw-in cartridge, poppet type pilot operated check valve for use as a blocking or load holding device.

Operation

The RP10A allows flow from port 2 to port 1, while normally blocking flow from port 1 to port 2. The valve remains closed by bias spring until sufficient pressure is applied at pilot port 3. The cartridge has 3:1 and 4:1 optional pilot ratios, meaning that at least one-third or one-fourth (respectively) of the load pressure held at port 1 is required at port 3 to open the valve. A sealed pilot piston option is available.

Features

- Hardened poppet to ensure extended service life and low leakage

- Additional reseating spring for fast and reliable closing

- Optional sealed pilot piston

- Higher flow rating and low pressure drop due to pilot port at 3.

- All external surfaces zinc-plated

- Industry common cavity

HYDAC Cartridge Valves

HYDAC Cartridge Valves Overview

RP16A-01

Check Valve, Pilot-to-Open, Poppet Type

Up to 40 gpm (150 l/min) • 6000 psi (420 bar)

Description

A screw-in cartridge, poppet type pilot operated check valve for use as a blocking or load holding device.

Operation

The RP16A allows flow from port 2 to port 1, while normally blocking flow from port 1 to port 2. The valve remains closed by bias spring until sufficient pressure is applied at pilot port 3. The cartridge has 3:1 and 4:1 optional pilot ratios, meaning that at least one-third or one-fourth (respectively) of the load pressure held at port 1 is required at port 3 to open the valve. A sealed pilot piston option is available.

Features

- Hardened poppet to ensure extended service life and low leakage

- Additional reseating spring for fast and reliable closing

- Optional sealed pilot piston

- Higher flow rating and low pressure drop due to pilot port at 3.

- All external surfaces zinc-plated

- Industry common cavity

HYDAC Cartridge Valves

HYDAC Cartridge Valves Overview

RV06A-01

Check Valve, Ball Type

Up to 5 gpm (19 l/min) • 5000 psi (350 bar)

Description

A screw-in cartridge, ball type check valve for use as a blocking or load holding device.

Operation

The RV06A allows flow from port 1 to port 2, while normally blocking flow in the opposite direction. The valve remains closed by bias spring until sufficient pressure is applied at port 1 at which time the ball lifts off the seat and allows flow from port 1 to port 2.

Features

- Hardened closing element to ensure extended service life and low leakage

- Multiple bias spring options for back pressure application flexibility

- Fast closing and seating

- All external surfaces zinc-plated

HYDAC Cartridge Valves

HYDAC Cartridge Valves Overview

RV08A-01

Check Valve, Ball Type

Up to 10 gpm (38 l/min) • 6000 psi (420 bar)

Description

A screw-in cartridge, ball type check valve for use as a blocking or load holding device.

Operation

The RV08A allows flow from port 1 to port 2, while normally blocking flow in the opposite direction. The valve remains closed by bias spring until sufficient pressure is applied at port 1 at which time the ball lifts off the seat and allows flow from port 1 to port 2.

Features

- Hardened closing element to ensure extended service life and low leakage

- Multiple bias spring options for back pressure application flexibility

- Fast closing and seating

- Low pressure drop

- All external surfaces zinc-plated

- Industry common cavity

HYDAC Cartridge Valves

HYDAC Cartridge Valves Overview

RV10A-01

Check Valve, Ball Type

Up to 21 gpm (80 l/min) • 6000 psi (420 bar)

Description

A screw-in cartridge, ball type check valve for use as a blocking or load holding device.

Operation

The RV10A allows flow from port 1 to port 2, while normally blocking flow in the opposite direction. The valve remains closed by bias spring until sufficient pressure is applied at port 1 at which time the ball lifts off the seat and allows flow from port 1 to port 2.

Features

- Hardened closing element to ensure extended service life and low leakage

- Multiple bias spring options for back pressure application flexibility

- Fast closing and seating

- Low pressure drop

- All external surfaces zinc-plated

- Industry common cavity

HYDAC Cartridge Valves

HYDAC Cartridge Valves Overview

RV12A-01

Check Valve, Poppet Type

Up to 31 gpm (120 l/min) • 6000 psi (420 bar)

Description

A screw-in cartridge, poppet type check valve for use as a blocking or load holding device.

Operation

The RV12A allows flow from port 1 to port 2, while normally blocking flow in the opposite direction. The valve remains closed by bias spring until sufficient pressure is applied at port 1 at which time the poppet lifts off the seat and allows flow from port 1 to port 2.

Features

- Hardened closing element to ensure extended service life and low leakage

- Multiple bias spring options for back pressure application flexibility

- Fast closing and seating

- Low pressure drop

- Fully guided check

- All external surfaces zinc-plated

- Industry common cavity

HYDAC Cartridge Valves

HYDAC Cartridge Valves Overview

RV16A-01

Check Valve, Poppet Type

Up to 44 gpm (165 l/min) • 6000 psi (420 bar)

Description

A screw-in cartridge, poppet type check valve for use as a blocking or load holding device.

Operation

The RV16A allows flow from port 1 to port 2, while normally blocking flow in the opposite direction. The valve remains closed by bias spring until sufficient pressure is applied at port 1 at which time the poppet lifts off the seat and allows flow from port 1 to port 2.

Features

- Hardened poppet to ensure extended service life and low leakage

- Multiple bias spring options for back pressure application flexibility

- Fast closing and seating

- Low pressure drop

- Fully guided check

- All external surfaces zinc-plated

- Industry common cavity

HYDAC Cartridge Valves

HYDAC Cartridge Valves Overview

RV06B-01

Check Valve, Integral Relief, Ball Type

Up to 4 gpm (15 l/min) • 5000 psi (350 bar)

Description

A screw-in cartridge, ball type check valve and direct acting, ball type relief valve combined in a single cartridge intended for use as load holding and pressure limiting device in hydraulic circuits to reduce manifold size.

Operation

The RV06B allows flow from port 2 to port 1 once the sufficient pressure is applied at port 2 to overcome the bias spring pressure of 5 psi (0.34 bar). It normally blocks flow in the opposite direction. The relief portion of the valve would remain closed until the predetermined pressure setting is reached at port 2 to lift the spring opposed ball from its seat, allowing flow from port 2 to port 3. Pressure at port 3 is directly additive to relief pressure setting.

Features

- Combination of two functions n one cartridge

- Relief setting up to 5000 psi (350 bar)

- Relief setting adjustment screw cannot be backed out of the valve

- Adjustable under full pressure

- Fast closing and seating

- Hardened closing elements to ensure minimal wear and extend service life

- All external surfaces zinc-plated

HYDAC Cartridge Valves

HYDAC Cartridge Valves Overview

RV06C-01

Check Valve, Integral Relief, Poppet Type

Up to 5 gpm (19 l/min) • 5000 psi (350 bar)

Description

A screw-in cartridge, ball type check valve and direct acting, poppet type relief valve combined in a single cartridge intended for use as load holding and pressure limiting device in hydraulic circuits to reduce manifold size.

Operation

The RV06C allows flow from port 2 to port 1 once the sufficient pressure is applied at port 2 to overcome the bias spring pressure of 5 psi (0.34 bar). It normally blocks flow in the opposite direction. The relief portion of the valve would remain closed until the predetermined pressure setting is reached at port 2 to lift the spring opposed poppet from its seat, allowing flow from port 2 to port 3. Pressure at port 3 is directly additive to relief pressure setting.

Features

- Combination of two functions n one cartridge

- Relief setting up to 5000 psi (350 bar)

- Relief setting adjustment screw cannot be backed out of the valve

- Adjustable under full pressure

- Fast closing and seating

- Hardened closing elements to ensure minimal wear and extend service life

- All external surfaces zinc-plated

HYDAC Cartridge Valves

HYDAC Cartridge Valves Overview

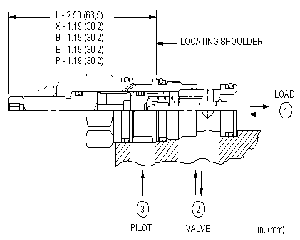

RVD08A-01

Check Valve, Dual Pilot-to-Open, Inline Body

Up to 10 gpm (38 l/min) • 6000 psi (420 bar)

Description

An inline housed, dual pilot operated, hydraulic check valve for use as a blocking or load holding device. The valve consists of two check valves and a dual pilot piston in an inline body.

Operation

The RVD08A allows flow from V ports to C ports, while normally blocking flow in the opposite direction. Flow will be allowed from C to V when pressure is applied at the opposite V port. The check is spring biased at 30 psi to assure holding in no load conditions. A sealed pilot piston option with check spring bias of 70 psi is available.

Features

- Hardened closing element in a check valve to ensure extended service life and low leakage

- Multiple bias spring options for back pressure application flexibility

- Optional sealed pilot piston

- Check section serviceable as a cartridge

- All external surfaces zinc-plated

- Aluminum and steel inline housing

HYDAC Cartridge Valves

HYDAC Cartridge Valves Overview

RVD10A-01

Check Valve, Dual Pilot-to-Open, Inline Body

Up to 21 gpm (80 l/min) • 6000 psi (420 bar)

Description

An inline housed, dual pilot operated, hydraulic check valve for use as a blocking or load holding device. The valve consists of two check valves and a dual pilot piston in an inline body.

Operation

The RVD10A allows flow from V ports to C ports, while normally blocking flow in the opposite direction. Flow will be allowed from C to V when pressure is applied at the opposite V port. The check is spring biased at 30 psi to assure holding in no load conditions. A sealed pilot piston option with check spring bias of 70 psi is available.

Features

- Hardened closing element in a check valve to ensure extended service life and low leakage

- Multiple bias spring options for back pressure application flexibility

- Optional sealed pilot piston

- Check section serviceable as a cartridge

- All external surfaces zinc-plated

- Aluminum and steel inline housing

HYDAC Cartridge Valves

HYDAC Cartridge Valves Overview

RVS08A-01

Check Valve, Single Pilot-to-Open, Inline Body

Up to 10 gpm (38 l/min) • 6000 psi (420 bar)

Description

An inline housed, pilot operated, hydraulic check valve for use as a blocking or load holding device.

Operation

The RVS08A allows flow from port V to port C, while normally blocking flow in the opposite direction. Flow will be allowed from C to V when pressure is applied at pilot port P. The check is spring biased at 30 psi to assure holding in no load conditions. A sealed pilot piston option with check spring bias of 70 psi is available.

Features

- Hardened closing element in a check valve to ensure extended service life and low leakage

- Multiple bias spring options for back pressure application flexibility

- Optional sealed pilot piston

- Check section serviceable as a cartridge

- All external surfaces zinc-plated

- Aluminum and steel inline housing

HYDAC Cartridge Valves

HYDAC Cartridge Valves Overview

RVS10A-01

Check Valve, Single Pilot-to-Open, Inline Body

Up to 21 gpm (80 l/min) • 6000 psi (420 bar)

Description

An inline housed, pilot operated, hydraulic check valve for use as a blocking or load holding device.

Operation

The RVS10A allows flow from port V to port C, while normally blocking flow in the opposite direction. Flow will be allowed from C to V when pressure is applied at pilot port P. The check is spring biased at 30 psi to assure holding in no load conditions. A sealed pilot piston option with check spring bias of 70 psi is available.

Features

- Hardened closing element in a check valve to ensure extended service life and low leakage

- Multiple bias spring options for back pressure application flexibility

- Optional sealed pilot piston

- Check section serviceable as a cartridge

- All external surfaces zinc-plated

- Aluminum and steel inline housing

HYDAC Cartridge Valves

HYDAC Cartridge Valves Overview

AVAILABLE IN THESE LOCATIONS

- Alabama

- Arizona

- Arkansas

- Kansas

- Louisiana

- Mississippi

- Montana

- N.W. Florida

- Nevada

- New Mexico

- Oklahoma

- S. Idaho

- Texas

- Utah

- W. Missouri

- W. North Dakota

- W. South Dakota

- Wyoming

Contact Us For Pricing And Availability

If you’re interested in any of our products, or you have any questions about pricing and availability, let our team know today. We’re here to help!