Sun Hydraulics

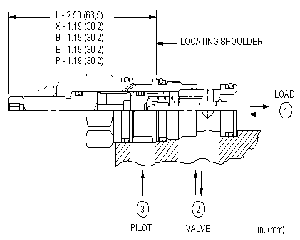

SUN Counterbalance Cartridge Valves

Womack Machine Supply Company proudly partners with Sun Hydraulics to deliver the finest Load Holding Valves available. Our collaboration ensures that customers in multiple locations across the United States have access to these exceptional products, click here to see available locations. Our commitment to excellence, combined with the reliability and performance of Sun Hydraulics, guarantees that you receive top-quality Load Holding Valves components for your specific needs.

- Offer hose break protection

- Prevent loads from drifting

- Control overrunning loads

- Provide overcenter load control

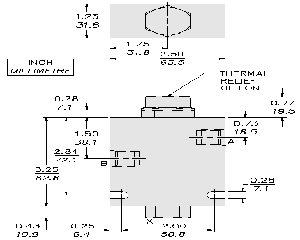

- Protect against pressure due to thermal expansion

- Are physically interchangeable with pilot-to-open check cartridges (same number of ports, same cavities, same flow path for a given frame size)

|

Standard, 4000 psi Maximum Setting

|

|

Standard, 5000 psi Maximum Setting

|

|

Semi-Restrictive, 4000 psi Maximum Setting

|

|

Semi-Restrictive, 5000 psi Maximum Setting

|

|

Restrictive, 4000 psi Maximum Setting

|

|

Restrictive, 5000 psi Maximum Setting

|

|

Without Pilot Assist, 3 Port Cavity

|

|

Atmospherically Referenced, 3 Port Cavity

|

|

Vented, 4000 psi Maximum Setting

|

|

Vented, 6000 psi Maximum Setting

|

AVAILABLE IN THESE LOCATIONS

- Arkansas

- Louisiana

- Oklahoma

- Texas

Contact Us For Pricing And Availability

If you’re interested in any of our products, or you have any questions about pricing and availability, let our team know today. We’re here to help!