Rollon

ROLLON Linear Actuators

Womack Machine Supply Company proudly partners with Rollon to deliver the finest Linear Modules available. Our collaboration ensures that customers in multiple locations across the United States have access to these exceptional products, click here to see available locations. Our commitment to excellence, combined with the reliability and performance of Rollon, guarantees that you receive top-quality Linear Modules components for your specific needs.

ONE Series

Belt driven linear actuator designed exclusively for Clean Room environments.

INTERNATIONAL PATENT PENDING for Series ONE (CLEANROOM CLASSIFICATION ISO 14644-1)

The ONE Series linear units are tested by the Fraunhofer Institute for Production Technology and Automation and have clean room ISO 14644-1 or FED STD 209E certification.

These linear units are typically used in:

- Semiconductor manufacturing

- Pharmaceutical production

- Biomedical applications

- Research laboratories

- Operational areas where contamination would cause production problems or pose a threat to people

ELM Series

This is Rollon’s highly versatile premier line of completely enclosed Belt driven-driven linear actuators.

The ELM is available in four sizes from 50 to 110 mm, it has a self-supporting structure with a robust square-section of extruded and anodized aluminum. The thrust force is transmitted by a steel reinforced polyurethane Belt driven. The moving carriage is precision guided and supported by a linear guide system or optional cam roller system. A polyurethane sealing strip guarantees a complete protection of the Belt driven and the linear guide system against dust, dirt, chips, liquids or other contaminants. It avoids the fragility of other sealing systems, including stainless steel strips.

The components used for linear motion –lubricant reservoir, caged ball bearing blocks, double-lip seals– promote a “maintenance-free” system. The pulleys, bearings and drive shafts are among the most robust in the industry. ELM is the best product for applications in very aggressive working environments that also require high speed duty cycles and position repeatability.

With the ELM series, corrosion-resistant linear units are now available for service in a difficult environment or which can frequently be cleaned. The self-supporting structure of the units, of extruded anodised aluminium with square cross-section, forms the basis of four different sizes in the series from 50 to 110 mm. Drive is through a steel-cord reinforced polyurethane timing belt, which according to choice is led over two linear guide blocks with caged ball technology or alternatively over track rollers.

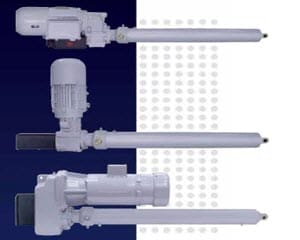

ROBOT Series

This is Rollon’s highly versatile premier line of completely enclosed Belt driven-driven linear actuators.

The ELM is available in four sizes from 50 to 110 mm, it has a self-supporting structure with a robust square-section of extruded and anodized aluminum. The thrust force is transmitted by a steel reinforced polyurethane Belt driven. The moving carriage is precision guided and supported by a linear guide system or optional cam roller system.

A polyurethane sealing strip guarantees a complete protection of the Belt driven and the linear guide system against dust, dirt, chips, liquids or other contaminants. It avoids the fragility of other sealing systems, including stainless steel strips.

The components used for linear motion –lubricant reservoir, caged ball bearing blocks, double-lip seals– promote a “maintenance-free” system. The pulleys, bearings and drive shafts are among the most robust in the industry. ELM is the best product for applications in very aggressive working environments that also require high speed duty cycles and position repeatability.

With the ROBOT series, corrosion-resistant linear units are available for service in a difficult environment or which can frequently be cleaned.

SC Series

The SC series is specifically designed for vertical motion in gantry applications or in those applications where the aluminum profile must move, while the carriage remains fixed.

Available in three sizes of 65mm, 130mm and 160 mm, it has a self-supporting structure made by a rectangular-section (square-section for SC 65) of extruded and anodized aluminum.

The SC is a very stiff vertical system, guaranteed by the use of two parallel linear guides and four “maintenance-free” caged ball bearing blocks and a very wide driving-Belt driven. The SC Series has been designed for heavy loads and high cycle applications. It is specifically designed and configured to be compatible and assembled with the ROBOT Series actuators without the need for adaptor plates.

With the SC series, corrosion-resistant linear units are available for service in a difficult environment or which can frequently be cleaned. The SC series is employed as a vertical unit in which the aluminium profile forms the moving part and the runner carriage the fixed element of the installation.

ECO Series

This is Rollon’s value-based solution to the problem of Belt driven linear actuators. By reducing the number of components and employing lean production methods, the ECO series is a high performance actuator with an attractive price.

There are three basic sizes with aluminum extrusion square cross sections of 60mm, 80mm and 100mm. The carriage is capable of supporting high loads due to the linear guide system installed in the extrusion. Either a recirculating ball linear guide system or a cam roller guide system are available.

The drive force is achieved through a steel reinforced industrial timing Belt driven. The impact of contamination can be minimized by the design and the protection afforded to the bearings by the Belt driven system and the robust extrusion. Rollon uses over-sized end bearings on the pulleys and drive shafts to prevent problems associated with misalignment, fatigue and high duty cycle use.

Light Series

The LIGHT Series has been designed for maximum simplicity and the highest possible thrust and load capacities while still maintaining high quality components and manufacturing standards.

The LIGHT Series is of an open frame design with exposed linear guides mounted on a rigid, lighter section extruded aluminum base structure. Power transmission is obtained by means of steel reinforced polyurethane Belt drivens ensuring high repeatability and good thrust load capacity.

The Light series is an economical choice where the duty cycle is not as severe and the working environment is relatively contaminant-free.

UNILINE Series

Uniline is a family of ready-to-install linear actuators. It is based on the COMPACT RAIL roller slider system with an aluminum profile. It is driven by a steel-reinforced polyurethane Belt driven. Uniline is completely sealed off with longitudinal seals and brushes at the feed-in and feed-out of the Belt driven.

- Motor connected with a solid or hollow shaft

- Strokes up to more than 3,000mm

- Available sizes from 40×51.5mm to 100×122.5mm

- Versions available with longer or multiple sliders

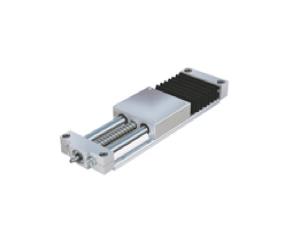

TH Series

TH actuators are rigid and compact linear units with ballscrew drive, enabling high positioning accuracy and repeatability in all process phases with optimal performance assured. Thrust force transmission is achieved by means of super high efficiency ball screws, which are available in several precision classes and a variety of leads. Linear motion is based on two or four preloaded recirculating ball bearing blocks — with ball retainer technology — mounted on two precision aligned parallel rails.

The TH series is available in the single carriage or double carriage versions to meet different load requirements. Use of these elements achieves optimal static and dynamic capacity and high positioning accuracy within 0,02 mm and repeatability within 0,005 mm. The TH series ensures maximum protection of internal components through use of extruded profiles, aluminum cover and two cross-linked polymer protection belts with molded-in polyester reinforced cables. Protection against external agents, dust, dirt and impurities is therefore ensured even in harsh working environments. TH linear units also feature safe and separate lubrication of guides and screws via a system of dedicated fittings and channels for each component. The extremely compact structure of the TH actuator makes it ideal for all limited space applications.

The actuator is currently available in the TH145 version with maximum strokes up to 1700 mm. The new TH110 version will be available soon with strokes up to 1400 mm.

The T-slots on the profile and threaded steel inserts on the carriages make the TH series completely modular and suitable for use in multi-axis systems. The TH series effectively meets the needs of all applications that require a high level of precision, compactness, protection and stiffness and it is an effective ready-to-use bolt-down solution for Engineers, Designers and Technicians requiring optimum performance in a linear motion system.

TT Series

The TT is a linear actuator series mainly used for high accuracy positioning within a 10 µm range and precision repeatability within 5 µm. Manufactured using a very rigid extruded anodized aluminum base structure and machined to 1 µm tolerances, this actuator series is designed for high loads and precise movements that are typically required in machine tools and other exacting machine design applications.

All mounting surfaces and reference datums have been produced to significantly reduce the deviations of pitch, yaw and roll along the entire stroke. The heavy duty carriage is driven by a C5 or C7 preloaded ball Ball screw driven and the payload is supported by a system of four runner blocks mounted on two parallel linear guides. High speeds can be accomplished by specifying available super lead ballBall screw drivens. The TT series contains all the necessary features and hardware to make multi-axis configurations and assembly easy. All TT units are 100% inspected and supplied with a certificate of accuracy.

TV Series

Linear units of the TV Series have a rigid anodized aluminum extrusion with square section (rectangular in the case of TV 140) with the transmission of motion achieved by means of a precision C5 or C7 rolled ball Ball screw driven.

The payload is supported by a dual block, single linear guide system (a dual block/dual guide system for TV 140) which ensures high precision and high rigidity.

The internal components of the TV series are protected with a stainless steel strip to help seal and prevent the ingress of contaminants.

TK Series

Series ‘TK’ is made entirely of steel.

This particular feature allows high load capacity, high precision positioning and repeatability with overall dimensions very content. This series can be dimensionally interchanged with other popular Ball screw driven driven actuators.

All mounting surfaces and reference are adjusted so as to ensure a high degree of dimensional accuracy. A ball Ball screw driven is used to transmit the force and position repeatability.

AVAILABLE IN THESE LOCATIONS

- Arkansas

- Louisiana

- Oklahoma

- Texas

Contact Us For Pricing And Availability

If you’re interested in any of our products, or you have any questions about pricing and availability, let our team know today. We’re here to help!